- Home

- Stretch Wrap

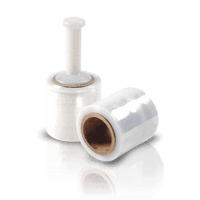

Stretch Wrap

Frequently Asked Questions (FAQ)

What is Stretch Wrap?

Stretch wrap is a polyethylene film product that is primarily used to secure pallet loads prior to shipping and maintain that security until the receiver unloads it at the other end of the shipment. It can also be used to bundle items together or to keep furniture clean during a move.

What types of Stretch Wrap are there?

Stretch film is available in blown cast and pre-stretch forms. Blown is the least expensive to manufacture, but cast gives greater strength in thinner gauges that perform better in most applications. Pre-stretch is a cast film that is literally “pre-stretched” so that it can be applied by hand and provide the same containment strength of an optimally machine-stretched film.

What is the difference between cast and blown film?

Blown stretch wrap is blown in bubble form, just like poly bags. Almost all blown stretch wrap is monolayer, offering high “tack” to provide a secure closure when wrapping is complete. Cast film is cast in a straight sheet format, and it can range anywhere from 3 to 11 layers or likely more one day. Eat layer provides a unique characteristic to the film, allowing for fine tuning, high strength and lower gauges compared to the blown counterparts.

What are the advantages and disadvantages of cast and blown film?

Blown film has two key advantages for hand wrap. 1. High tack, resulting in secure closure of the wrapped item, and 2. Soft pliability that is good for resisting punctures from sharp objects. Cast film is made to provide controlled characteristics that suit the intended applications best. In general, cast film is stronger at lower gauges, making it the least expensive when compared per foot, even though it is higher priced per pound.

When should I use stretch film?

Stretch film is generally the most economical means of containment for outgoing shipments, whether those be palletized loads or bundles of long, narrow objects. Available in quantities as small as one roll and up to truckloads, it is well suited to everything from one-time use in a move, all the way up to multiple stations wrapping non-stop on 24/7 shifts.

How do I know what size of film to use?

When properly applied, stretch film will become more narrow as it is stretched. So an 18 roll, for example, will “neck down” to as few as 14” when optimally stretched. Blown films neck down more than cast films, and cast film more than pre-stretch. If applying by hand, the most common sizes range from 11” to 20” in width. Machine films begin at 20” in width and typically step up in 10” increments up to 60”. The wider the film, the fewer rotations required to contain around a pallet, but the more narrow films are lighter and can better suit short pallet loads and certain bundled applications.

What is equivalent stretch film?

Equivalent films are high performance stretch wrap rolls that perform equal to heavier gage counterparts. Many 43 gauge films of today, for example, perform as well as the original 80 gauge stretch films of the past. Even present day conventional films often underperform their “equivalent” replacement films, as there are many old lines running the original 3 layer technology of the past. The exact definitions are defined by the provider, as there is no industry standard for B=A when it comes to equivalency, and it's highly recommended that you start with small quantities and test any new film for suitability to your application.

Should I use UV stretch film?

If a wrapped item will be outdoors or otherwise exposed to direct sunlight, UV films can give you much longer package integrity by resisting degradation. Your DPB Packaging Consultant will be happy to help you determine if this is the right choice for you.

What is pre stretch film?

Pre-stretch gives you the memory resistance of machine film with the convenience of hand film. By mechanically “pre-stretching” high quality cast films, this film is already at the optimum point to contain your load as if it were wrapped on high end machines, but without the investment in the equipment or logistic challenges of moving loads around to the wrapping station. It is also lighter per roll and puts less strain on the back of the user.

When should I consider using a stretch wrap machine vs hand film?

Wrapping by machine offers the ability to custom tailor the amount of film and the stretch of that film, resulting in the best containment of your load, lowest cost per optimized pallet, higher speed and fewer worker compensation claims resulting from back injuries sustained while manually wrapping film around your product. The financial formula for answering this question is pretty easy to do. Simply total the number of hours spent wrapping per day and divide those by the cost of the machine. That will give you an approximate time for a machine to pay for itself. You'll also need to estimate the amount of stretch film to be saved per load, the cost of labor to set and remove the pallets from the machine and the saving from reduced damage in transit that will result from properly containing every load.

What is the difference between stretch wrap and shrink film?

Stretch film is stretched to contain products on pallets or in bundles. Shrink film and bags are heated to shrink around the products that they are going to contain. Your DPB Packaging Consultant may be able to help you determine which method is going to be best suited to your application.

What are the most important criteria in choosing a stretch film?

You will want to consider the number of packages to be wrapped per day/week/month, the weight and height of the loads to be contained, the value of the product being wrapped and the method of applying the film to the package. Choosing the right stretch film can be challenging, but your DPB Packaging Consultant is trained to assist you in this process.

What is the benefit of stretch wrap in industrial containment?

Stretch film has many benefits. Originally designed to replace pallet shrink bags and the high energy ovens that shrink them, stretch film has done nothing but grow in the number of applications for which it is found to be well suited. Properly applied stretch film can not only protect loads against shifting in transit, but also against pilferage, damage, moisture (When paired with a top sheet) and dust & dirt.

Is stretch film recyclable?

Stretch film is made from various versions of LLDPE which is 100% recyclable.